Stereolithography (SLA)

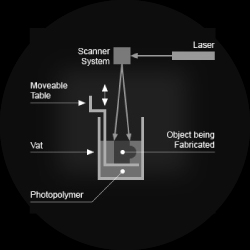

An SLA Prototype (Stereolithography) is built by passing a laser over a vat of resin and ‘growing’ the SLA Protoype, layer by layer.

Once the first layer is completely traced by the laser, it's lowered a small distance into the vat and a second layer is traced right on top of the first. The self-adhesive property of the material causes the layers to bond to one another and eventually form a complete, SLA Prototype after many such layers are formed.

LAE Technologies is used by material manufacturers as a beta testing platform for many new, cutting edge materials. Thus, our materials list is constantly expanding for SLA Rapid Prototyping.

SLA is one of the original 3D printing technologies and has a very wide range of material that make it applicable to just about every industry. SLA printing’s inherent properties allow for very fine features, down to thousands of an inch are possible. SLA printing can also produce optically clear parts that can be used in the bottling industry, aerospace, automotive and anywhere that a window or part clarity might come into play. SLA printing can also produce flexible parts, ideal for mimicking polypropylene.