Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS Printing) is additive manufacturing with which you can create durable, metal, plastic, or rubber-like prototypes on a SLS 3D printer directly from any 3D CAD model in as little as one day.

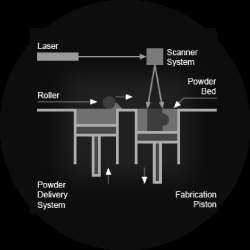

The data from a 3D CAD file is entered into the SLS 3D Printer. A precise, thin layer of heat fusible powder is deposited across the build platform of the SLS 3D Printer.

A computer controlled carbon dioxide laser scans a cross section of the 3D SLS Prototype. As the laser draws the cross section, the powder contacted by the laser is fused together, without actually melting the powder, forming a thin layer (typical 0.004"). A new layer of powder is deposited and the process of selective laser sintering and spreading powder is repeated until the SLS Prototype is complete.